Drillsoft: Drilling Software & Automation

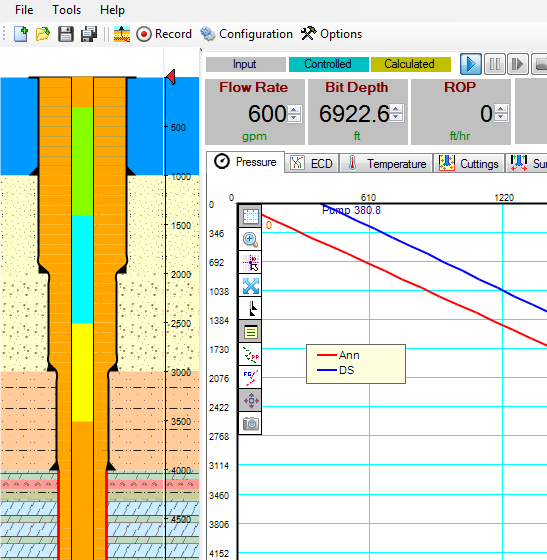

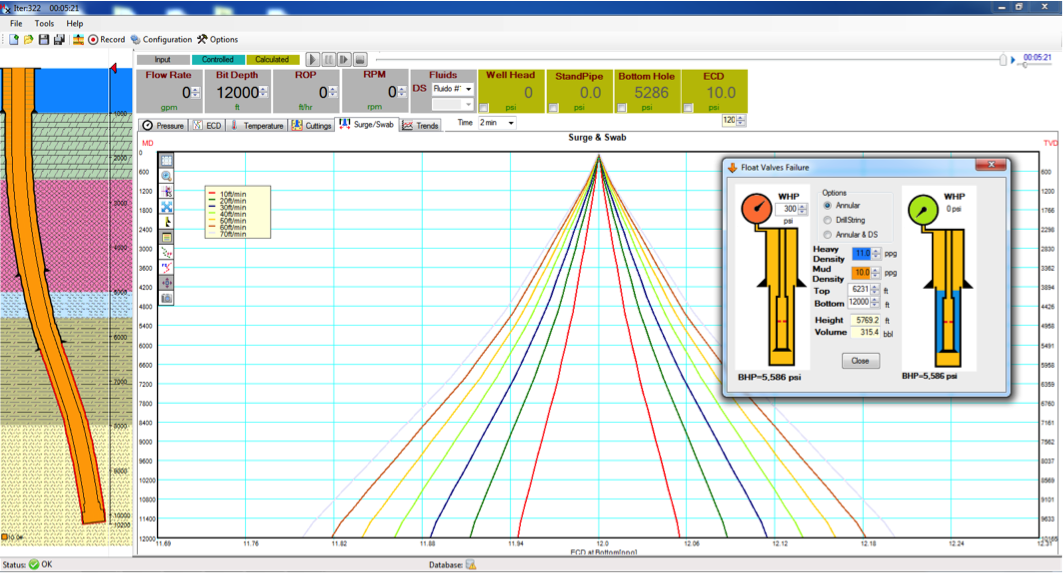

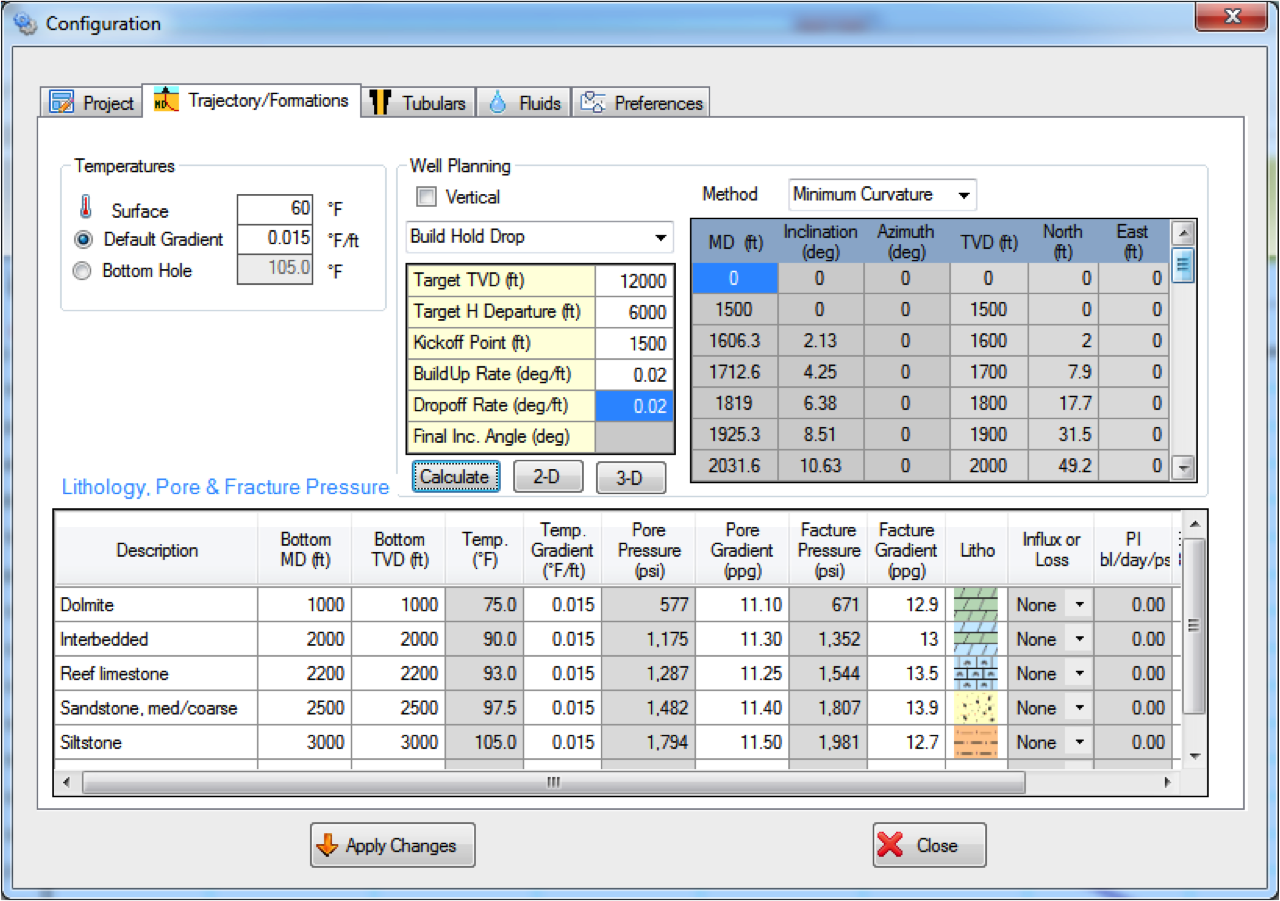

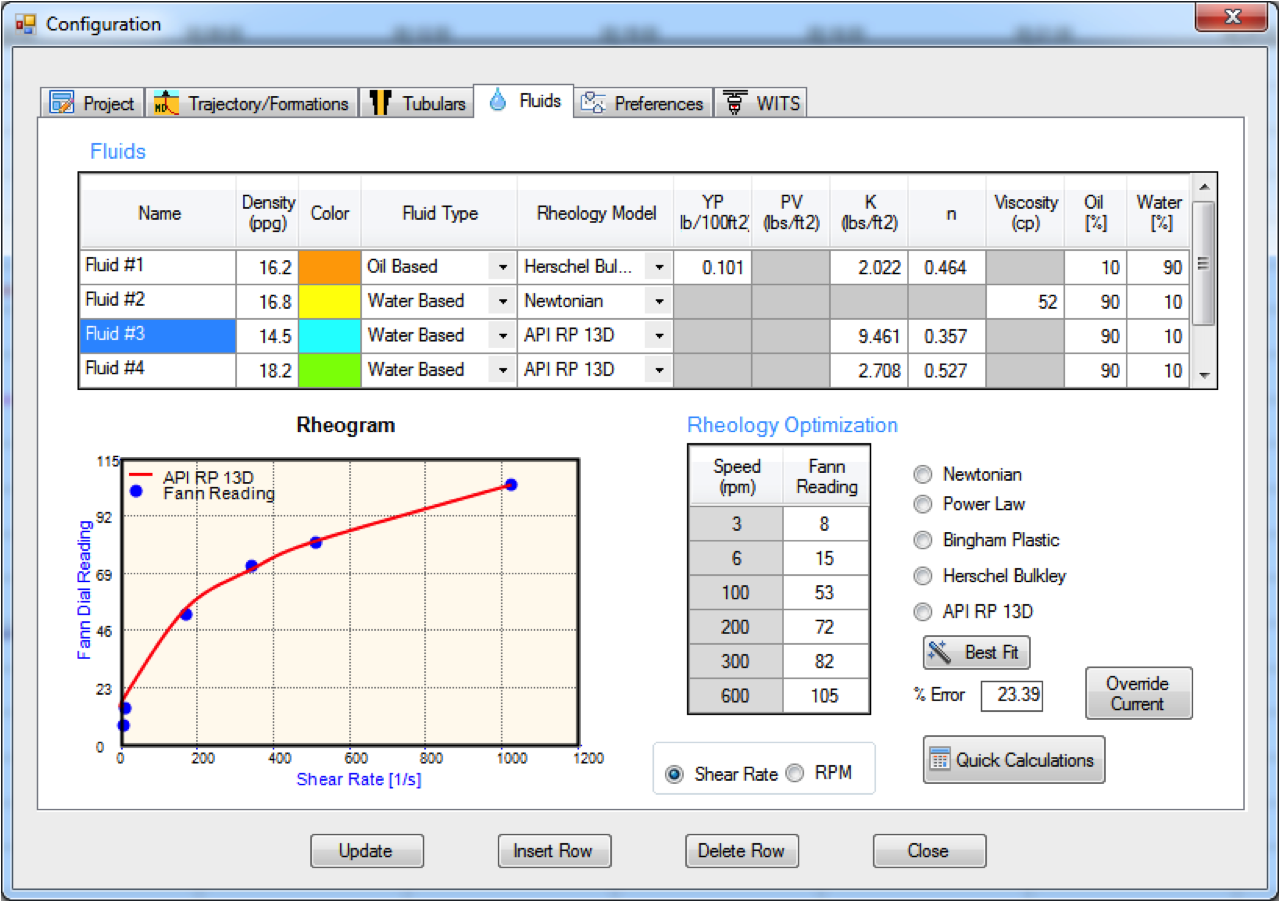

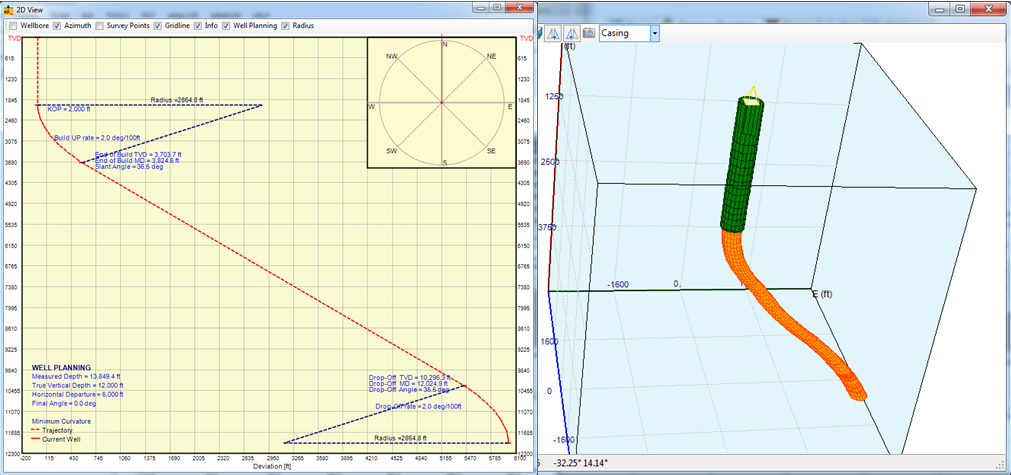

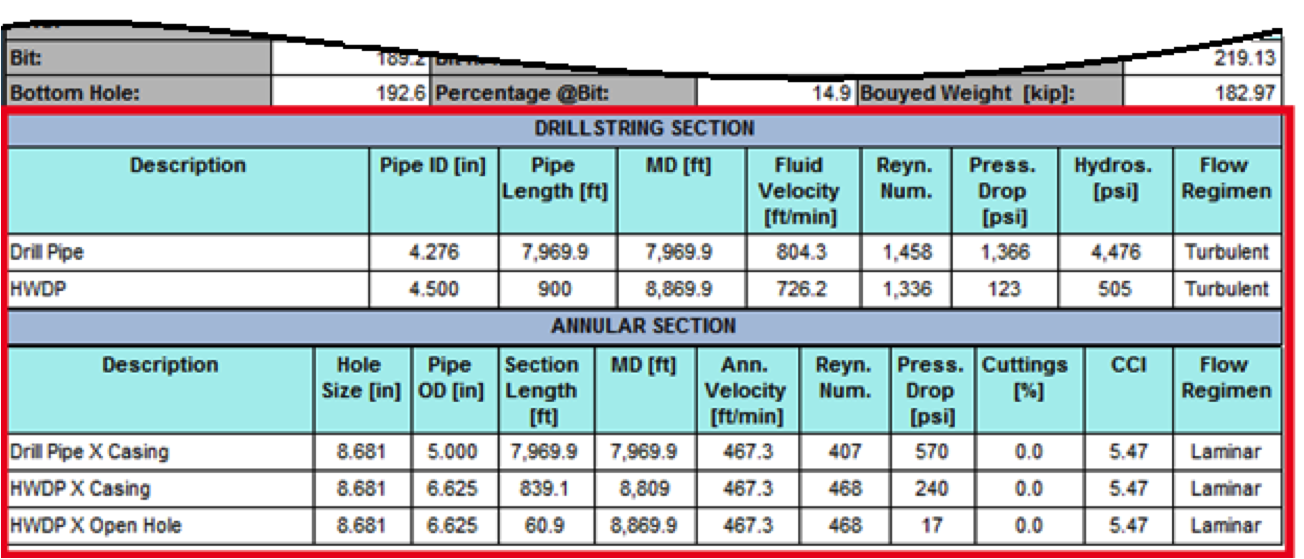

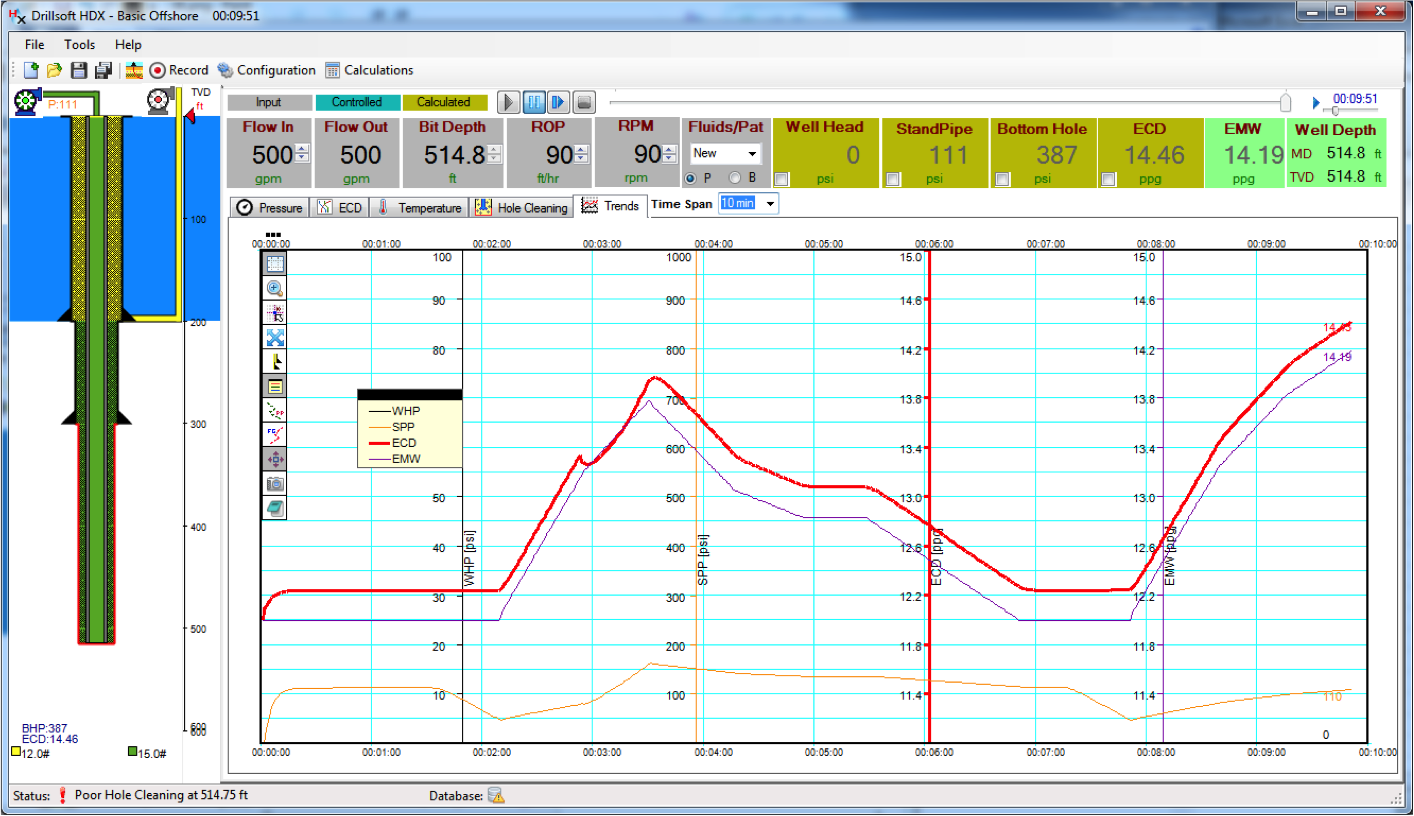

Drillsoft is a platform for hydraulic applications or simulators for Dynamic Pressure Drilling (MPD/UBD) or conventional drilling. Our real time hydraulics Software focuses on drilling hydraulics and modeling wellbore pressures and temperatures during all phases of the drilling operation in extended-reach, highly deviated, horizontal and high temperature and high pressure (HTHP) wells. The simulator uses state of the art algorithms and provides the user with a wide range of modeling options. The simulator includes a well trajectory and planning model well directional profiles, whether computed or imported from other directional survey service providers. The well trajectories will be displayed in 3-D profile. Drillsoft calculates and evaluates down-hole temperatures during drilling, circulating and shut-in operations for land and deep-water wells. A finite difference mathematical model has been developed to predict well bore and formation transient temperature behavior during drilling, fluid circulation and shut-in operations. This includes wells with multiple temperature gradients and well bore deviations, based on the fluid’s physical characteristics. The PVT model accurately calculates ECD and ESD according to formation and wellbore temperature profiles.

Drillsoft calculates and evaluates down-hole temperatures during drilling, circulating and shut-in operations for land and deep-water wells. A finite difference mathematical model has been developed to predict well bore and formation transient temperature behavior during drilling, fluid circulation and shut-in operations. This includes wells with multiple temperature gradients and well bore deviations, based on the fluid’s physical characteristics. The PVT model accurately calculates ECD and ESD according to formation and wellbore temperature profiles.