Customers’ inquiries of better services lead to invention of new features

URM

One day one of our clients called and asked a question about hole size increase by using an under reamer. We took on the objective to create a simple to use addition for under-reamer where the hole is enlarged by opening an under-reamer below the casing shoe. The obstacle was incorporating the diameter change in the open hole section to be larger than the casing, the calculation changes, the new friction factors, and the volumes. After spending a few days we completed the request. The feature was easy to use by adding the three letter URM into any section in the drillstring and changing the tooljoint diameter to the diameter of the open under-reamer. After testing the feature and confirming that it was fail-proof, and passed our in house quality control check, the client was given the update. They were able to test the feature and returned with positive feedback. Following this positive feedback, we released the update to all clients and across all of our software packages.

Jet Nozzle

A client of ours who has extensively used our software had came into an issue where they had used multiple jet nozzles set along their drill string. The goal was to help lift cuttings and optimize the necessary pump rate to achieve hole cleaning with the flow rates through the jet nozzle. They wanted to be able to adjust the Total Flow Area (TFA) and achieve the desired flow rate and hole cleaning efficiency. We began working on implementing this into Drillsoft HDX+. Our goal was to implement the feature in such a way that it doesn’t only simulate hole cleaning efficiency but also include the temperature changes that are created with having flow from the DrillString mix with the mud in the annulus. One important factor to consider was also the new friction created by having mud being flown out of the drill string at various depths. We successfully implemented the system and made it as user friendly as possible so that the user can access and optimize their TFA and flow rates through the jet nozzles without having to go through extra learning time. The new update was released within 2 weeks from the date it was requested following extensive quality control testing and discussions with the client. This feature is now available to all of the DrillSoft HDX+ users. And can be easily accessed by typing JetSub in any drill string component row and double clicking on it to see the TFA, Flow Percentage and Flow rate through each nozzle.

Riserless Drilling

During a marketing meeting where we presented our software to an offshore completions company, we were asked about simulating the pre-BOP Riserless Pump and Dump Drilling Operation. This was not something implemented in any of the DrillSoft Software before. However being able to simultaneously have multiple different muds in the well it was a simple feature to implement. After working for 2 days we were able to allow the user to eliminate the riser and simulate a riserless pump and dump drilling operation. The components that are important here to consider was the change in volume when the riser is removed, the new temperature profile with a cooler ocean temperature directly interacting with the returning mud in the annulus, and the heat transfer between the sea/ocean and the drillpipe and mud in the drillpipe. After verifying the stability and accuracy the feature was included in Drillsoft HDX and 3 days after the request was made, the feature was released to all DrillSoft HDX users. The feature was made so that no extra learning is necessary to activate the riserless drilling feature. We just added a disable button next to the riser in the configuration window. The user is able to see a breakdown of the volumes, flow rates, friction factors and temperatures and verify that the software is simulating Pump

and Dump.

Tool Joint Correction Factor

During a meeting with a client, they gave us feedback on the correction factors and requested the ability to adjust the ToolJoint Length. By default we had restricted the Tool Joint length to 10% of the overall length of the pipe section. After the discussions we began implementing the feature to allow users of all DrillSoft software to be able to customize their ToolJoint length by adding a box into the Tool Joint Correction Factor window. The user can customize the overall ToolJoint length by changing the percentage and choose a desired value. The new feature was released within 2 days of the request was made.

Pressure/Temperature Correction Factor

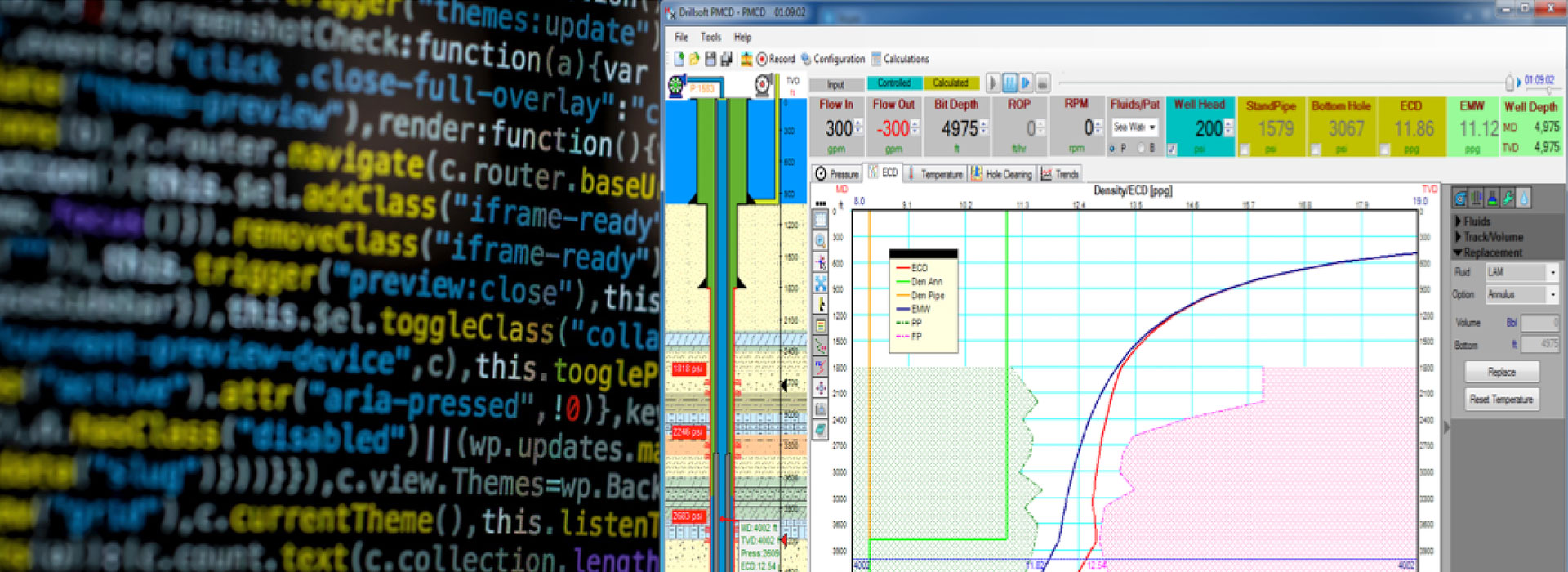

At Drillsoft we are always trying to provide you with the most accurate software with many features included to simulate the hydraulics of any operation from conventional drilling to riserless pump and dump operation, to deepwater HPHT MPD operation with Oil and Synthetic Based Mud. We are always open to feedback from our clients to implement new features or improve existing features and models. One task we recently undertook was to change and improve our Pressure and Temperature model with an improved empirical model for deep HPHT wells. We used information available in literature to implement the models. The result was improved accuracy to accommodate the density increase due to compression of the mud with higher pressure and the density decrease due to swelling and expansion of the mud with higher temperatures. Implementing this new Pressure/Tempeature into the density wasn’t the only task but also to include it into the rheology, viscosity, friction and overall hydraulics model of the software. After implementing these changes and running quality control tests we released the new model in all Drillsoft software updates. Following the update we received countless positive feedback for this update.

Leave a reply