VBlog

- Home

- VBlog

- All

- News

- Oil & Gas

Customers’ inquiries of better services lead to invention of new features

URMOne day one of our clients called and asked a question about hole size increase by using an under reamer. We took on the objective to create a simple to use addition for under-reamer where the hole is enlarged by opening an under-reamer below the casing shoe. The obstacle was incorporating the diameter change in

Hydraulics Optimization

Sometimes Drilling engineers overlook this simple but important concept about hydraulic performance and optimization. We are not reinventing the wheel here, I’m just suggesting use your knowledge and apply it. The concept of Hydraulic Optimization is based on the best condition to clean the well is when the force provided by the jets is the

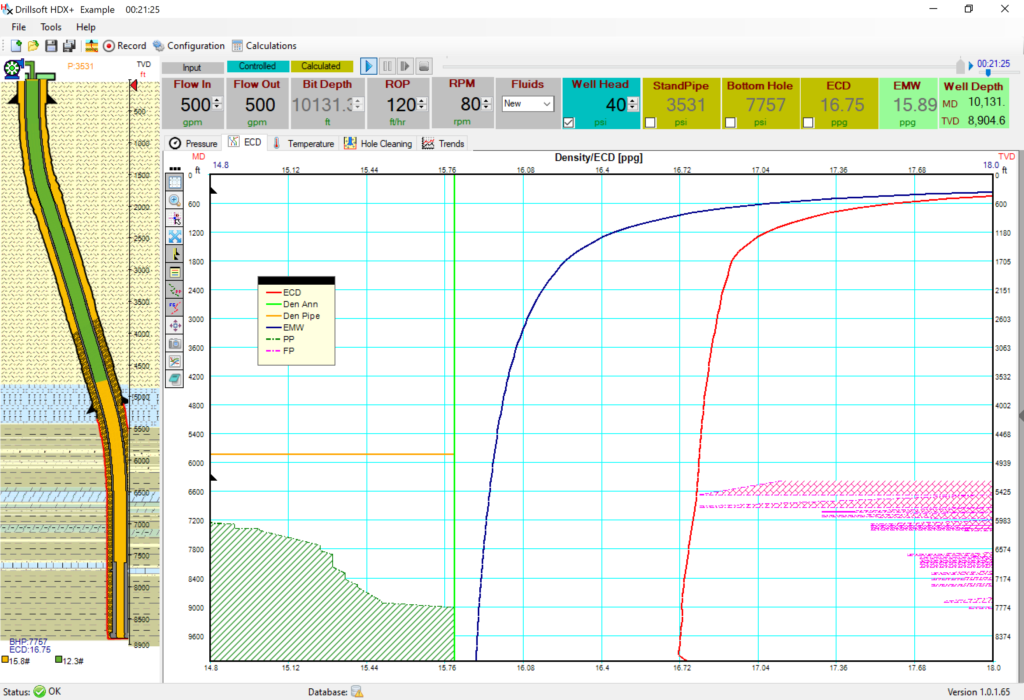

Importance of Hydraulic Planning Prior to Drilling a Well

There are multiple components that go into planning and designing a successful plan. But the importance of the Hydraulic Planning cannot be ignored as it alone can be a determining factor whether or not the well will reach planned TD. But the hydraulics don’t only allow for the well to reach TD, but also affects

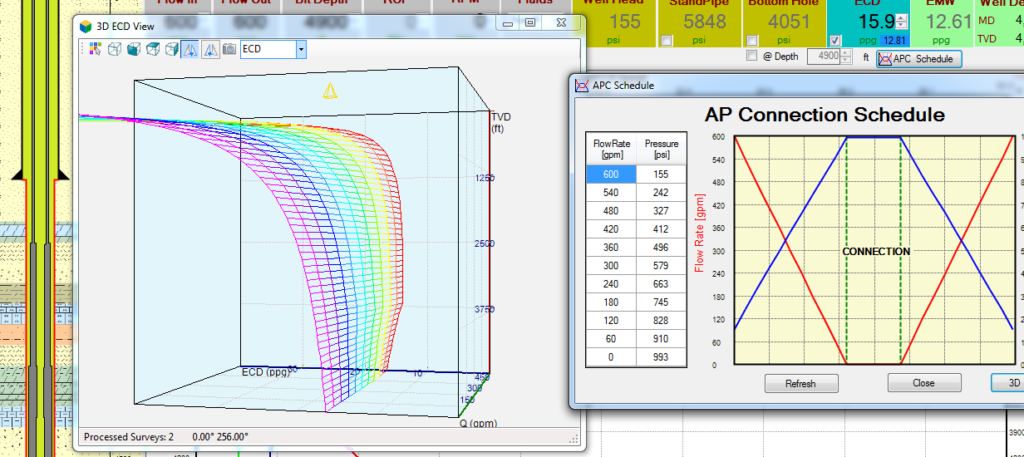

Have you seen a MPD connection in 3D?

Check this article to see how looks like the MPD connections in 3D. During MPD connections we replace the annular friction by applying surface back pressure to achieve the target bottom hole pressure or target ECD. This effect “bends” the annular profile to achieve the desire bottom hole pressure. Imagine a sheet of paper and

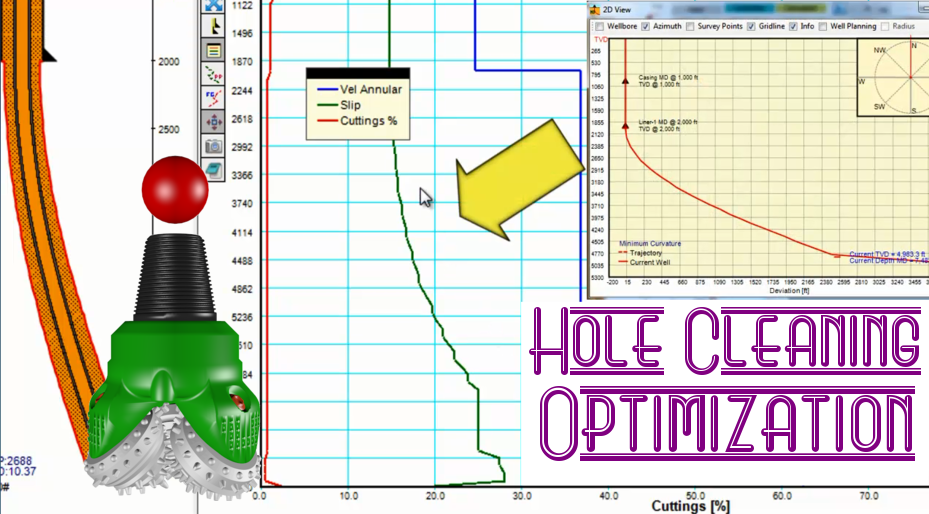

Hole Cleaning Problems? See How to Optimize Cuttings Transport and Drilling Hydraulics

Optimal Hole Cleaning Drilling fluid hydraulics and hole cleaning is an integral part of the practical processes required for planning and drilling a well. Optimization of cuttings transport depends on so many factors- hole angle, cutting size, drill string rotation, drill pipe eccentricity, optimization of bit hydraulics, ROP, hole cleaning pills, cuttings transport ratio, cuttings

Unveiling the real differences between drillers and ‘wait and weight’ methods

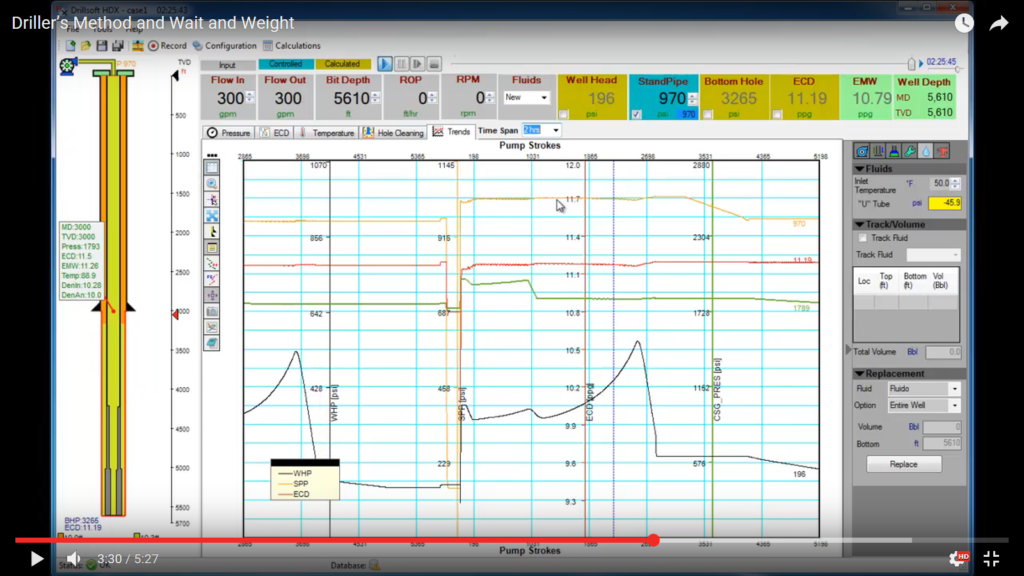

It’s very well-known and documented the pros and cons between these two methods, we show you the real or numeric quantification between them using both methods under the same conditions. In the video, you will see a simulation of 10 barrels gas influx controlled using both methods, at the end you will see the comparison

Enlarging Wellbore in MPD operations: watch out the friction!

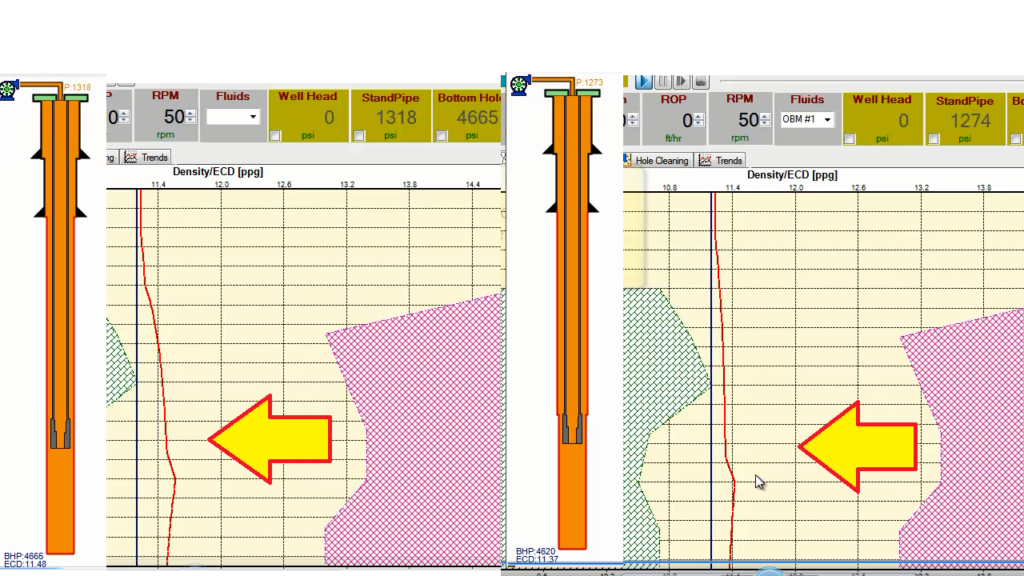

During under-reaming operations the annular friction varies as you go deeper. Since you are enlarging the wellbore the annular velocity decreases hence the friction in the section under-reamed, but at the same time the total or cumulative friction increases since the total length of the drillstring is larger, no mention the surge effect which in

Surge and Swab effect during your simulation (RIH/POOH)

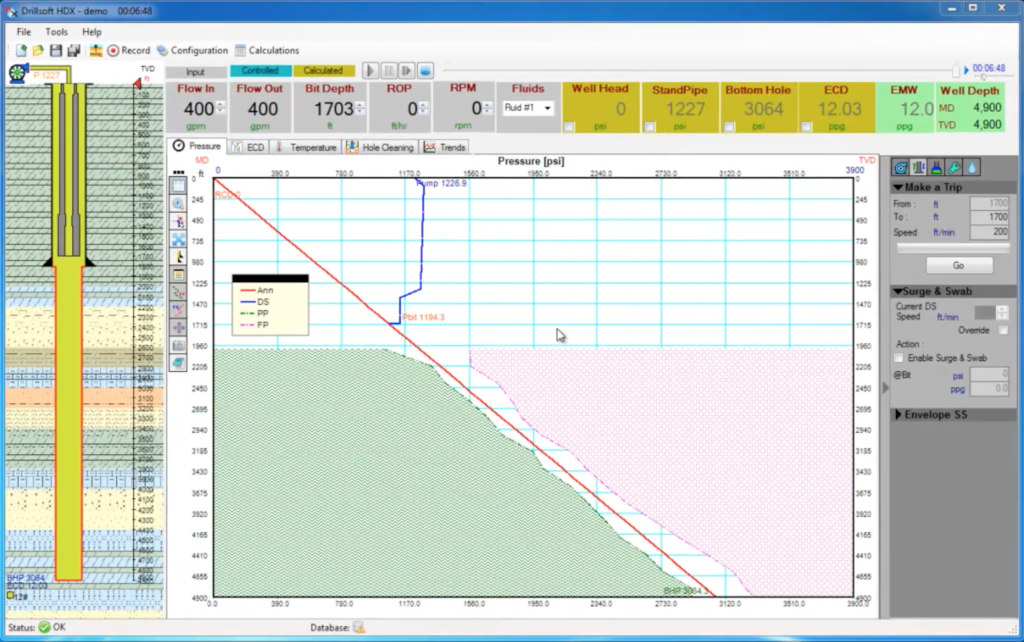

This video shows the Surge and Swab effect while tripping (RIH/POOH) and how we can incur in losses even though the bottom ECD seems fine and still we are far from bottom fracture pressure/ECD. Don’t miss it!! This generally happens in “weaker” formations below the casing/liner shoe, so we need to pay special attention not

Transient differences from steady-state calculations?

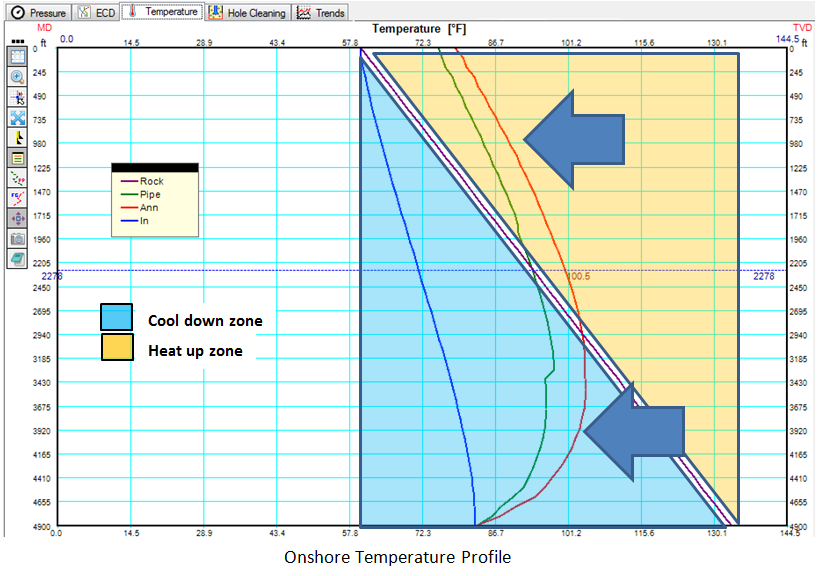

The important effect of Temperature. The transient Temperature effect is very important in the accuracy of MPD/UBD calculations. Most people ignore this effect perhaps because they don’t have the right tools to calculate the transient effect, so many engineers just take the thermal gradient and use steady state formulas to calculate the bottom hole temperature.

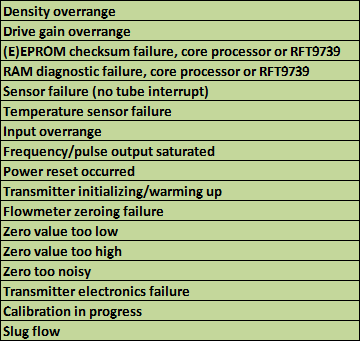

Get the Most of Coriolis Flow Meters. Improve Your Operations with This Advanced Diagnostics

Generally in MPD/UBD operations and drilling companies use devices to measure flow in and flow-Out. The most common device nowadays for flow_out is a Coriolis flow meter (mass flow meter), because this technology is reliable and offer measurements not only flow but density, temperature among others. There exist a variety of these Coriolis flow meters

Find out what are the maximum pressures you can handle an influx safely.

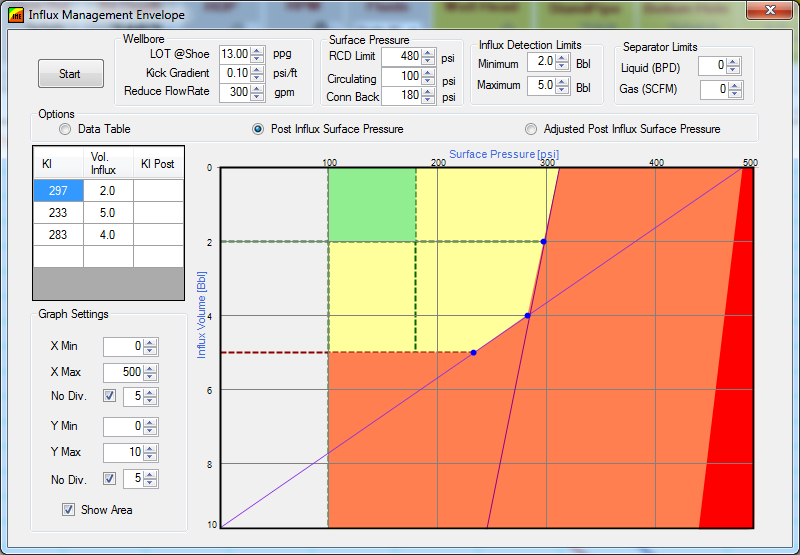

Question: How do you know is the MPD Operation matrix is “safe”? RCD Limit: 450 psi LOT: 13 ppg Min Influx allowed while drilling: 2 Bls* Max Influx allowed while drilling: 5 Bls* * Data as per company’s polices Answer: Run IME and check safe influx values. The objective Influx management Envelope (IME) is determine